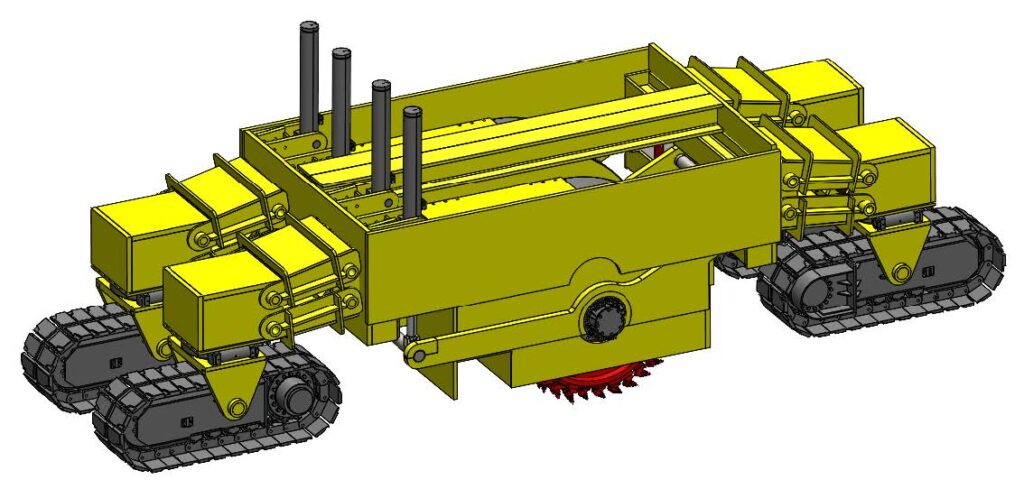

The MPI Block Tie and Slab Rehabilitation System has dual 14” wide x 72” diameter cutting surfaces on one common drum and is designed to grind two 14” wide X 8” deep cuts simultaneously in one pass.

The grinder weighs 120,000 pounds and is powered by two 300hp hydraulic motors. Hydraulic power is produced by two, truck mounted, 300hp Cat C7.1 Tier 4 Final diesel engines.

All hydraulic components are manufactured by Danfoss. All electric components are manufactured by Allen Bradley.

When in work mode, the grinder travel track and depth of cut is controlled by a Trimble Total Station Guidance System to ensure defined track geometry. The horizontal travel speed of the cut is controlled by the operator. When in travel mode, MPI’s operator also controls general movement as needed.

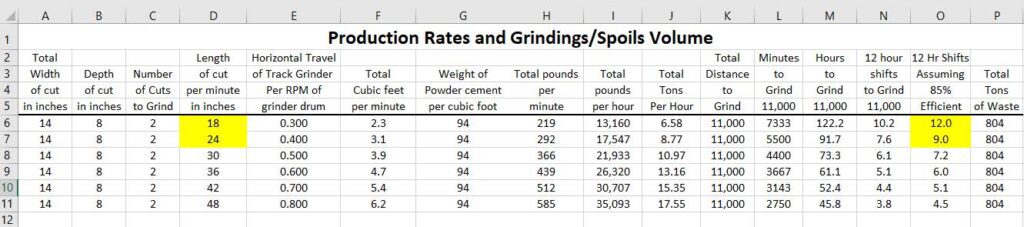

Based on two cuts this size, we project a work speed of 18” to 24” per minute. Depending on production time availability, the grinding process could be completed in a minimum of 12 twelve-hour shifts assuming 85% efficiency.

Grindings/spoils are discharged via conveyor into a dump truck. Fine mist sprays are used to control dust.

During the grinding process, track retaining bolts may be ripped out, broken, bent over or grinded away.

Specs:

- Machine operating weight: 120,000 pounds

- Width of cut: Two 14” wide

- Maximum cutting depth: 8” below the surface of the concrete

- Controls: Remote control

- Hydraulic components: Danfoss

- Travel speed: 600 feet/hour

- Work Speed: See chart below

- Drive system: Tracks

- Drive type: Hydraulic

- PLC controls: Allen Bradley